- Ellerhold Group

- Machine-manufacturer

- MLM_2600_NG

Why did we develop the MLM_2600_NG?

How it all started...

The goal was to automate the manufacturing process for Mega-Light posters. Previously, this involved the use of four individual printed sheets that had to be manually assembled into a single poster.

The process began by laminating the printed sheet sections with a thin film by running them through a special machine. Then they had to be cut in the cutting center and placed on an assembly table for gluing together. The four printed sheets were glued together with a minimal overlap.

Next, the edge of the poster was reinforced with tape, another element ("clip tape") and a functional label were applied, and finally the poster was cut to the desired size. The goal was to optimize the time consuming single steps and to automate the production of Mega-Light posters.

Four becomes one

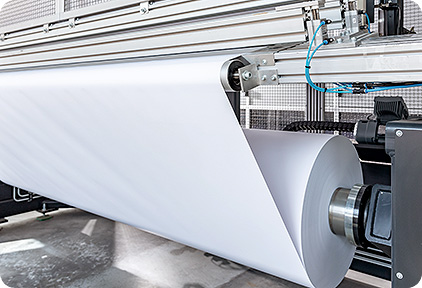

The desire for a 1-piece poster production has existed for a long time. However, offset printing does not have such large machine formats and digital printing was too expensive. Only the development of our own digital printing machine solved the format problem, as well as the aspects of economy. Paper rolls are constantly being transformed into Mega-Lights, column posters or StretchPoster - all in one piece.Additional back side printing

Consistent quality of the MegaLight posters is important to us. To ensure that the poster motifs retain their optimal color brilliance in the twilight and evening hours, the poster motif is also printed mirrored on the back. This creates a slide like effect and the changed light influences – from the front during the day and from behind at night – are compensated. Thus, the posters have a consistent, colorful appearance, no matter what time of day.

Assembly included

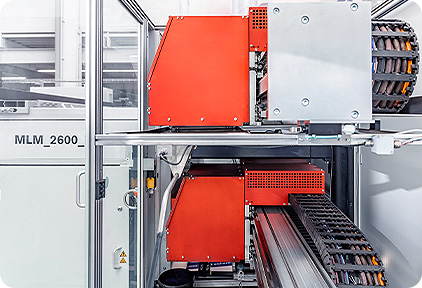

Printing alone does not make a finished Mega-Light. This requires a wide range of steps - starting with double-sided printing, lamination, edge trimming, application of the "clip band", edge reinforcement, application of a functional label (Bero mark), through the cross-section, transporting of single Mega-Light to the delivery table and finally rolling up for shipment. A highly complex interplay of mechanics and digital technology, controlled by powerful software.All features of the MLM_2600_NG

Double-sided printing

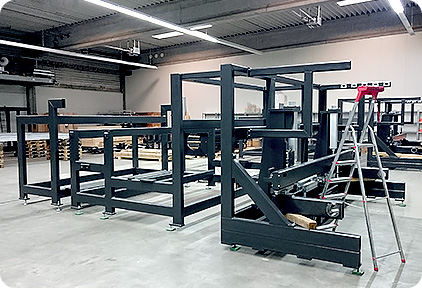

Thanks to a total of 32 print modules for the front and 16 print modules for the back, a perfect 4/4-color print image is produced. This enables a consistent display quality of the Mega-Lights, regardless of the changing light sources during poster posting.Our installed MLM_2600_NG

Contact us - we look forward to hearing from you

You are interested in our products?

You are interested in our machines? Feel free to contact us – we look forward to hearing from you!

This is what our customers say

Bratislava

Bittner Print Ltd.

„You can't build B-cutters for high-end industrial printers like the Aleph Laforte 400 that can keep up with the production speeds of these machines. That's why both Alephs are absolute A-class printers in the industrial world together with the Ellerhold Group. Ultra fast cutting lines, Poster-Cutter 2050.“ (Show original language)

@bittnerprint (Facebook)

Witten

Ellerhold Witten GmbH

„The production of mega-light posters for outdoor advertising used to be extremely time-consuming and personnel-intensive. This changed with the introduction of the MLM machines. All processing steps are carried out completely "in line" there. The production stability, reliability and high quality of the machine are particularly noteworthy. In case of problems, Ellerhold Maschinenfabrik GmbH provides fast and unbureaucratic support. In short: Made in Germany has a name here again!“ (Show original language)

Thomas Koch, Abteilungsleiter

Prag

Astron Print s.r.o.

„The negotiations with the representatives of Ellerhold were very friendly, personal and human. All agreements are kept and everything runs as it should. Another strong argument in favor of the Poster-Cutter 2050 is the fact that Ellerhold has been using these cutters in its own production for quite some time. This means that the development department always has strong feedback from real production.“

Martin Kliment, COO

Prag

Astron Print s.r.o.

„After careful consideration, we decided to integrate the Ellerhold Poster-Cutter 2050 cutting machines into our new production lines. Almost one year of continuous operation of two Poster-Cutter 2050 has shown us that this decision was the right one, which is why we decided to install a third one this year.“

Martin Kliment, COO

Stay up to date with our newsletter.